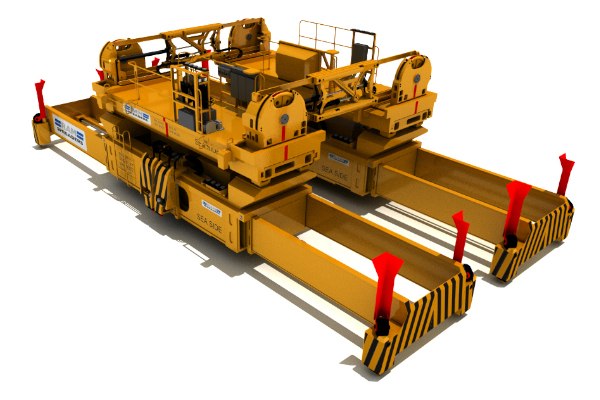

RAM6100 Tandem Headblock

SingFlex®

SingFlex® is an adjustable tandem headblock for ship to shore cranes. The tandem headblock allows you to handle two container spreaders at once, which is ideal for customers who want to boost their container handling productivity and reduce energy demand/costs.

The tandem headblock, SingFlex®, is capable of handling multiple containers in a single hoist lifting operation and is electro-hydraulically operated with all functions of the headblock controlled from the crane operator’s cabin.

SingFlex can be retrofitted to most container handling cranes by ISO floating twistlocks connecting the tandem headblock to the spreaders.

Quick change over between single spreader to twin spreader is fully automated and is done within 2 minutes without assistance from support staff. The switch over takes place in the headblock's very own docking station.

Technical

Lifting Capabilities:

Single Spreader – Main Headblock

1 x 20ft|40ft|45ft* ISO containers

Twin Spreader – Main & Second Headblock

2 x 20ft | 40ft | 45ft* ISO containers

4 x 20ft

Adjustments:

Gap between containers | 0 – 1600mm

Longitudinal Offset | 0-200mm

Skew | +/- to 3 degrees

Height Adjustment between containers | 0 -550mm

(*subject to spreader capability)

Benefits

Improve your productivity

Lifting more containers per lift cycle increases quayside productivity.

Save Energy

Operating with a tandem headblock will not only increase lifts per cycle but reduce energy consumption. This will also lead to terminals saving on energy costs whilst having a faster container operation.

Increase safety & speed of change-over

RAM’s unique quick automatic change-over between spreaders increases quayside safety and reduces the time it takes to change between single and twin spreaders, meaning the crane operator can easily plan ahead without disrupting lifting operations.

Flexibility

Crane operators have the flexibility to control the gap, skew, longitudinal offset and height difference between containers.

Media

Press Articles

Demand for Tandem Headblock Grows

The transition between single and tandem container lifting

The battle between single vs dual hoist cranes for tandem lift operations

Over 120 headblocks now in operation

Case Studies

Trends in Tandem Lifting

Tandem Lift Energy Saving Benefits

RAM SingFlex Headblock of choice in comparison selection

Videos

Further Info

Certification

All RAM spreaders are manufactured at our purpose built production facility in accordance with ISO 9001:2008:2008, ISO 14001;2004 and DIN 18800-7 welding standard.

Fully Tested

All spreaders are fully load tested, function tested and are delivered together with operation and maintenance manuals and associated certification.

Warranty

All RAM Spreader products are supplied with full equipment warranty.