Key Takeaways

- Ship to shore headblocks are a cost effective alternative to dual hoist cranes

- Less maintenance and breakdowns are expected with a headblock, due to fewer components

- Ship to shore headblocks can still operate in tandem without being restricted

- Tandem lifting on a ship to shore crane is increasing in popularity

Why an extra 2 million USD is a poor investment for STS tandem lift operations.

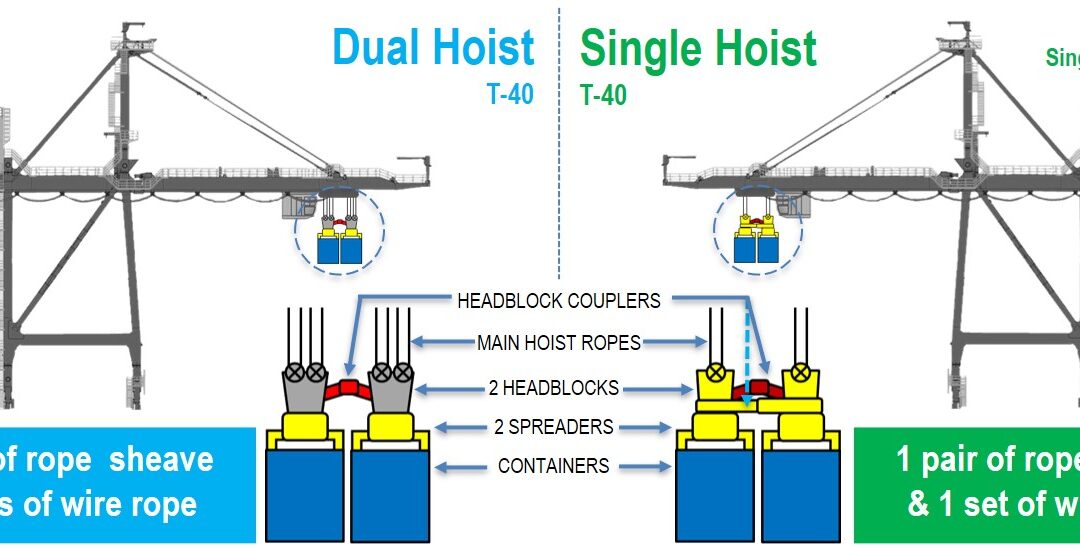

Since their introduction in the mid-1980s, dual hoist ship to shore cranes, with their two independent sets of hoists for double lifting have been used by ports and terminals, to help increase productivity by up to 50%, with the double handling of containers. However, this increase is often offset by higher operational and running costs compared to single hoist STS crane operations.

So how can ports and terminals increase productivity whilst keeping operational costs to a minimum? This article compares the differences between dual and single hoist crane container handling and highlights the increasing trend and benefits in single hoist tandem lift operations to boost productivity.

Capital Investment

On average, ports and terminals would need to find an extra 2 million USD per dual hoist crane compared to a single hoist crane. The additional investment equates to the additional amount of steel and components making up the dual hoist crane, and the additional quayside groundwork needed to support the heavy dual hoist crane and its operation.

In comparison, to achieve the same outcome and objectives as a dual hoist crane, a single hoist crane with a tandem headblock attachment, carries with it a significantly smaller investment, from the reduced amount of steel needed, fewer components, and no groundwork modifications.

Crane Restrictions

By investing large amounts in STS cranes, you would expect to take full advantage of its capabilities. Though with a dual hoist crane, its utilisation will be restricted due to various conditions including a terminal’s current equipment, its size, stacking plan, container system coordination and the type of vessels permitted to berth.

In the case of single hoist cranes with tandem headblock systems attached, container terminals can still accommodate large Panamax container vessels, operating in tandem mode, taking full advantage of a single hoist crane’s capabilities, without compromising operations. This is possible, in the case of the RAM ship to shore headblock and twin lift ship to shore spreaders beneath with a low overall height of just 3 meters from the sheave centre to the bottom of the spreader, allowing a crane operator to reach out to that 24th row of an ever-increasing capacity mega vessel.

Breakdowns and Maintenance

A dual hoist crane is comparatively more likely to require more downtime due to an increased number of components compared to a single hoist crane. This increase in downtime with dual hoist operations inevitably increases operational costs.

Are single hoist operations more sustainable?

With a single hoist crane and tandem headblock, a terminal moving 100 (40ft) containers will be able to achieve this within 50 moves, whereas a dual hoist crane in tandem mode, will achieve this in 100 moves. This allows terminals to decrease their quayside operational energy demand by 15%, whilst reducing their costs and improving their productivity.

From Single to Tandem

By using tandem (RAM SingFlex), once a crane operator has placed the single spreader into the dedicated docking station located on the crane beam, a simple button click will allow the transition from single to twin spreader (and vice versa) to take place. The transition is done without any manual intervention and completed within 2 minutes. It is the only tandem headblock system with this time-saving automatic change-over functionality.

A growing trend in single hoist tandem

Dual hoist crane operations have since stopped in various locations, such as Durban, Saudi Arabia, UAE, Germany, and Santos Brazil, and for RAM they have seen a growing trend in the number of locations around the globe that have now adopted RAM SingFlex Tandem, including terminals in Dubai, London UK, The Netherlands, Belgium, Mexico, China and Singapore.

With the current global container crisis, a tandem operation will no doubt become the “new normal” for the way containers are handled in a bid to cope with the increasingly growing global demand to move more containers from bigger than ever container vessels.

The question will be if terminals opt for a dual hoist crane or a single hoist crane with headblock attachment for a tandem operation?

Frequently Asked Questions

What is the main difference between a dual hoist crane and a single hoist crane with a headblock attachment?

Dual hoist crane utilization can be limited due to various factors, including equipment compatibility, terminal size, stacking plans, container system coordination, and vessel type restrictions. Single hoist cranes with headblock systems attached offer more flexibility and can still accommodate large Panamax container vessels.

How do breakdowns and maintenance differ between dual hoist and single hoist cranes?

Dual hoist cranes are more likely to experience increased downtime and maintenance needs due to their greater number of components. This increased downtime translates to higher operational costs. Single hoist cranes with headblock attachments are more reliable and have lower maintenance requirements.

How Does the SingFlex Headblock Address Tandem Lifting Challenges?

The SingFlex headblock is designed with a high degree of flexibility, enabling precise adjustments in container gap, longitudinal offset, skew, and height. This adaptability proves instrumental in addressing challenges posed by containers positioned at varying distances and heights. For a demonstration of SingFlex’s flexibility in tandem lifting, watch our animated video.

What is Tandem Lifting?

Tandem lifting is a container handling technique where a crane hoists two container spreaders at the same time, increasing port productivity and efficiency by handling multiple containers simultaneously. Read our blog post to learn more – What is tandem lifting?

Want to learn more about the ship to shore crane headblock?

Head to the ship to shore crane headblock product page.