In our latest newsletter, we discuss our latest updates, product developments & our COVID-19 approach.

Newsletters

Newsletter – September 2019

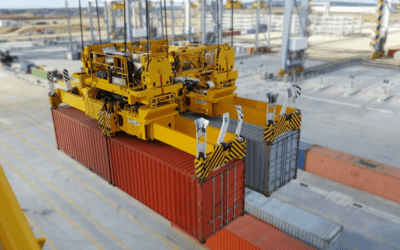

Find out what RAM has been up since their last Newsletter back in September 2018, from new product developments, case studies into the challenges of pipe handling and the drive for automation with the future of twistlock handling.

Newsletter – September 2018

Our newsletter looks at our business activities over the previous months, our container spreader sales and the activities of our aftersales team.

Newsletter (February 2018)

Find out what RAM have been up since their last Newsletter back in Feb 2017, from a new product launch, customer news, a new “how to” video and special features on the SMAG STS Grab and RUT Biomass Export.

Newsletter (February 2017)

Since our last newsletter in September 2016 we have achieved many successes in the last quarter of 2016. As a result of an independent report we saw ports and terminals leaning towards the benefits of using single hoist cranes for multiple container lifts. The report produced for a port in Asia conducted a cost and operational analysis between single hoist and dual hoist cranes for multiple container lifting and compared headblock connections from three different spreader equipment manufacturers.The report recommended for ports to consider using single hoist cranes. More significantly, the RAM SingFlex headblock connection was identified to rank first in a number of test parameters.

Newsletter (September 2016)

Since the launch of our first newsletter in April, we have kept busy, preparing for a very special event which represents a pivotal milestone in the history of RAM Spreaders – the official retirement of our founder Mr Robert A. Mills. After over 40 years of dedicated hard work, will retire from RAM this year.