RAM4000 PinSmart

Fully Automated Twistlock Handling Machine

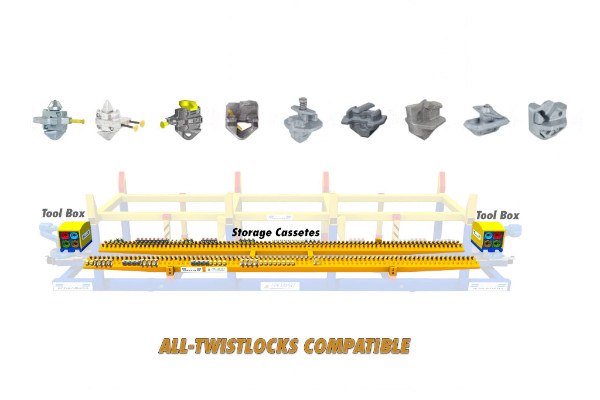

The pace for port automation is now starting to accelerate and the PinSmart II will fill the gap of automating the removal and replacement of ISO twistlocks. The machine’s robotic smart arms are designed to handle all types of twistlocks, enabling a faster more efficient container operation. PinSmart can be retrofitted to a quayside or a drive-through operation.

With the advancement of technology, port automation is now accelerating. The PinSmart II is designed to fill port automation's last challenge 'twistlock handling'. The machine is fully automated, removing and replacing all types of ISO twistlocks in ship to shore quayside or drive-through operations.

The automated machine will support up to 80 tonnes and is shock damped to reduce shock transfer, impact and noise. Gather guides are located at each axis to guide container(s) into position, where the robotic arm(s) then remove or replace the container's twistlock cones.

PinSmart II can be fitted with up to four smart robotic arms. The more robotic arms will reduce the removal/replacement of the twistlock cone cycle.

Twistlocks are taken to or fed from the large-capacity storage racks - capable of handling up to 2,000 twistlock cones. The self-learning robotic arm can memorise each twistlock type and its exact position.

The machine is powered by a simple plugin from the quay crane.

Technical

| Feature | Description |

| Twistlock removal/replace time | 10 seconds* |

| Twistlock types | All types |

| Container sizes | 1 x 20ft/40ft/45ft/2 x 20ft |

| Storage capacity | 2,000 twistlock cones |

Benefits

A faster quay crane cycle

The intelligent robotic arm can remove/replace a twistlock within 10 seconds. The cycle can be further advanced through fitting more robotic arms, which means more twistlocks being removed/replaced.

Improve operational safety

PinSmart II removes the element of danger, as the robotic arm acts autonomously at the quay side. This also means insurance costs will be reduced, saving on port expenses.

Smart Storage

The PinSmart II has 2,000 twistlock storage spaces. The intelligent robotic arm will remember where each twistlock type is stored.

Save on labour costs

The automated machine does not need any manual intervention and as a result, save on operating expenses.

Operate in all weathers

The PinSmart II can operate in all weather conditions.

Save Energy

Optimised container flows reduce energy consumption emissions, improving port sustainability and reduce port expenses.

Further Info

Certification

All RAM spreaders are manufactured at our purpose built production facility in accordance with ISO 9001:2008:2008, ISO 14001;2004 and DIN 18800-7 welding standard.

Fully Tested

All spreaders are fully load tested, function tested and are delivered together with operation and maintenance manuals and associated certification.

Warranty

All RAM Spreader products are supplied with full equipment warranty.