RAM Spreaders attended the 2023 International Bulk Journal awards and won the safety award for their RAM Revolver.

Press Releases

read more

RAM Refurbishes Revolvers for Port Kembla

RAM Spreaders refurbished a rotating spreader for their customer LINX Port Services Pty Ltd in Port Kembla Australia, who handles dry bulk.

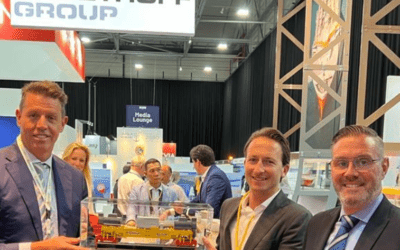

RAM Presents Spliethoff Pipe Spreader Model

RAM Spreaders was at the Breakbulk 2023 event, where they presented their first pipe spreader customer with a scale model.

RAM progressing with eco-friendly business initiative

RAM on their way to completing their Eco-friendly business initiative.

TPS incorporates a new containerized copper transfer

Experience cutting-edge dry bulk handling at Terminal Pacífico Sur Valparaíso, utilizing hermetically sealed flip containers and advanced 360° rotating spreaders for safe and efficient copper concentrate handling.

RAM provides hands-on port training in remote Africa

Our regional manager for Africa delivers mobile harbour crane spreader training for a remote port in Africa

Recent Posts

RAM Spreaders win the IBJ Safety In Bulk Handling Award 2023

RAM Spreaders Refurbishes Revolvers for Port Kembla

RAM Spreaders Present Spliethoff with Pipe Spreader Model

RAM on their way to completing their Eco-friendly business initiative

TPS incorporates a new containerized copper transfer service