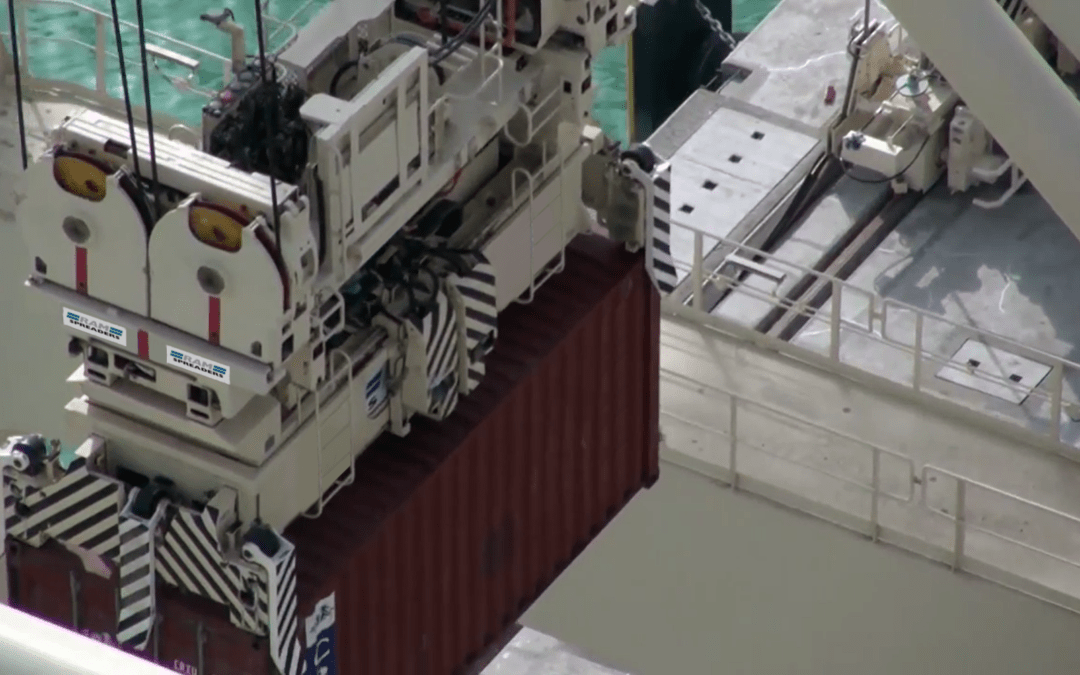

RAM Spreaders has made significant strides with major new orders at DPW London Gateway and Jebel Ali. In the United Kingdom, DPW London Gateway Container Terminal, a renowned technology leader situated on the north bank of the River Thames in London, has recently acquired 8 units of RAM Spreaders’ SingFlex ship to shore headblock and 18 units of their RAM CenterSpread twin lift ship to shore spreaders. Notably, these spreaders come equipped with RAM’s innovative ‘ShockAbsorbTM’ technology, designed to minimize noise and impact.

Moving across the globe to the Middle East, we find DPW investing in Phase III of Jebel Ali, poised to become a technological marvel of its generation. In this endeavour, DPW has placed an order for 19 units of the ‘SingFlex’ tandem headblock and 40 units of RAM’s ‘CentreSpread’ twin lift ship-to-shore crane spreaders. Additionally, DPW has made a strategic move by acquiring 50 units of Automated Rail-Mounted Gantry Cranes equipped with RAM 3920 All-Electric ship-to-shore spreaders. These spreaders boast hi-torque electric flippers, replicating the mechanical simplicity and benefits of hydraulic flippers.

Complementing this significant order and the growing spreader fleet in the Middle East, RAM Spreaders has appointed a Regional Technical Manager who will be stationed at a newly established office in the Jebel Ali Free Zone. Philip Lee, RAM’s CEO, emphasizes that the decision to assign a Regional Technical Manager to Jebel Ali is driven by the need to provide support not only to Jebel Ali but also to the extensive spreader fleet scattered across Oman, Yemen, Saudi Arabia, Qatar, Kuwait, and Egypt.

Furthermore, RAM Spreaders has taken a vital step by entering into an agreement with World Crane Services (WCS), a Jebel Ali-based company. WCS will be responsible for stocking and distributing spare parts to Jebel Ali and other regional customers. Philip Lee underscores the importance of this move, saying, “It is crucial to cater to the requirements of our clients, particularly in the Middle East. Thus, we decided to establish a central office to offer assistance and support while maintaining an extensive stock of spare parts to reduce lead times.”

Philip Lee adds, “As spreader technology advances, having readily available spare parts becomes paramount to ensuring a quick response to the needs of local clients. A substantial parts inventory in Dubai enables us to promptly meet the spare parts demands of the UAE and our regional clients.”

In keeping with its longstanding tradition, RAM Spreaders has welcomed William Job, an electrical engineer with over a decade of experience in the port industry. William’s role is to provide regional RAM customers with the necessary support to maintain the high reliability of their spreaders. He is enthusiastic about this new challenge and looks forward to working closely with clients in the region.

With over a decade of development dedicated to perfecting the ‘SingFlex’ headblock, RAM Spreaders eagerly anticipates continued success as more ports make the informed choice of adopting the RAM ‘SingFlex’ for tandem and quad lifts.

About RAM Spreaders and NSL Engineering Pte Ltd

Since the company’s earliest designs saw the light of day almost 40 years ago in England, RAM Spreaders has grown to become the world’s clear No2 in container handling spreaders and the No1 independent supplier. Now part of NSL Engineering Pte Ltd, a major industrial group with construction, chemical, property, technology and investment interests, RAM Spreaders has manufacturing and development facilities in Singapore, a manufacturing plant in China and an assembly and servicing facility in Lancashire, England.

Recent developments include the new All-electric separating twinlift design, and a telescopic spreader designed for mobile harbour cranes. These new series join the existing RAM range of telescopic, fixed and separating twinlift spreaders, offering a reliable choice for ship to shore spreaders, yard crane spreaders, mobile harbour crane spreaders, and containerised bulk handling.

Issued for NSL Engineering. Tel +65 6867 3380 (Singapore), For further information contact Cameron Hay of RAM Spreaders marketing@ramspreaders.com

Frequently Asked Questions

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Why is 'ShockAbsorbTM' technology important for ship to shore spreaders?

‘ShockAbsorbTM’ minimizes noise and impact during container handling, reducing disturbances.

Why did RAM Spreaders appoint a Regional Technical Manager in Jebel Ali?

RAM appointed a Regional Technical Manager to support Jebel Ali and clients across the Middle East, enhancing service and maintenance.

What's the role of World Crane Services in RAM's operations?

World Crane Services (WCS) plays a key role in stocking and distributing RAM genuine spare parts, ensuring rapid support in the region.