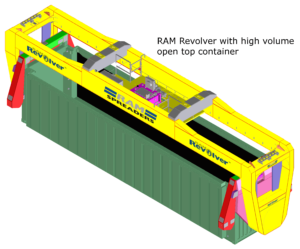

RAM Spreaders develops high volume Revolver – Container combination for low density bulk

In order to meet the need of our customers who wish to handle low density dry bulk products, we at RAM have developed a high volume ‘Revolver® – Container’ combination, to add to our extensive range of container handling solutions.

With a growth in biomass and other low density dry bulk materials, we have been investigating ways to maximise the efficiency of loading with our customers. Essential to the investigation process and the feedback we received, was the need and ability to load large volumes (>100 cubic meters) per cycle.

After consulting with customers RAM has developed a solution with the ‘Revolver® – Container’ combination being able to handle this level of load rate, by introducing a high volume container capable of achieving a higher volume load capacity.

This new innovation allows the Revolver® to handle large volumes and provide our customers in getting the very best load rates available.

With a maximum volume of standard open top containers being limited, it ultimately restricts its efficiency. So you would think to increase the volume, you would have to introduce an out of gauge container, which would be expensive to build and to ship.

To solve this problem, we have developed a two tier container, which is an ‘in gauge’ design solution for shipping but out of gauge for operations. So for the customer it will increase efficiency but still remain cost effective.

The design and construction of the high volume ‘in gauge’ container is innovative and very easy to introduce into the containerised bulk handling process.

The key areas of the design and construction of the container:

1. A wider container which is capable of being shipped ‘in gauge’ and then easily assembled on site

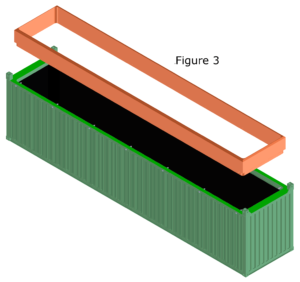

2. A top insert, capable of making the container taller which is shipped ‘in gauge’ and easily assembled on site.

These new innovations enable the customer to ship the container ‘in gauge’ and then assemble the container to the larger volume capacity on site.

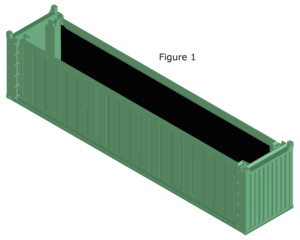

This can be seen in figure 1 where the side walls of the container are at their standard ISO ‘in gauge’ width for shipping purposes.

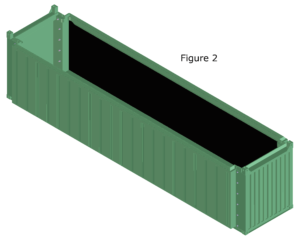

Then on site figure 2 shows the side walls being extended past the ISO width and bolted to the end walls.

The same occurs with the container height extender as shown in figure 3, which is based on the old concept of “hungry board” which could enable the container to be shipped in gauge but be extended beyond ISO dimensions.

These innovations form part of our commitment to innovation and providing the best solution to our customers.