RAM Spreaders introduces a new pit-to-port rail system that uses top lift Revolvers to handle ore.

This is a revolutionary alternative to expensive bottom dump or rotary railcar dumpers, which are expensive and involve long lead times.

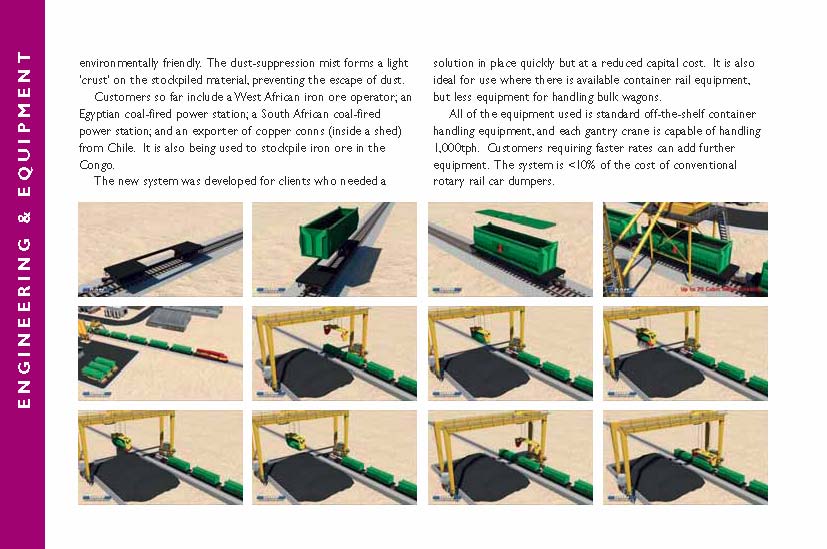

The system includes a large gantry that straddles the rail tracks at the receiving stockyhard, and the crane accross the gantry literally picks up a 20ft or 40ft container that is carried by the railcar, lifts it across to the required part of the stockpile, and empties the contents of the container onto the stockpile before returning it to the train.

Read the full Dry Cargo International editorial published October 2015

by clicking the following link: Railcar emptying system (DCIOCT15)