Built upon generations of experience and innovation

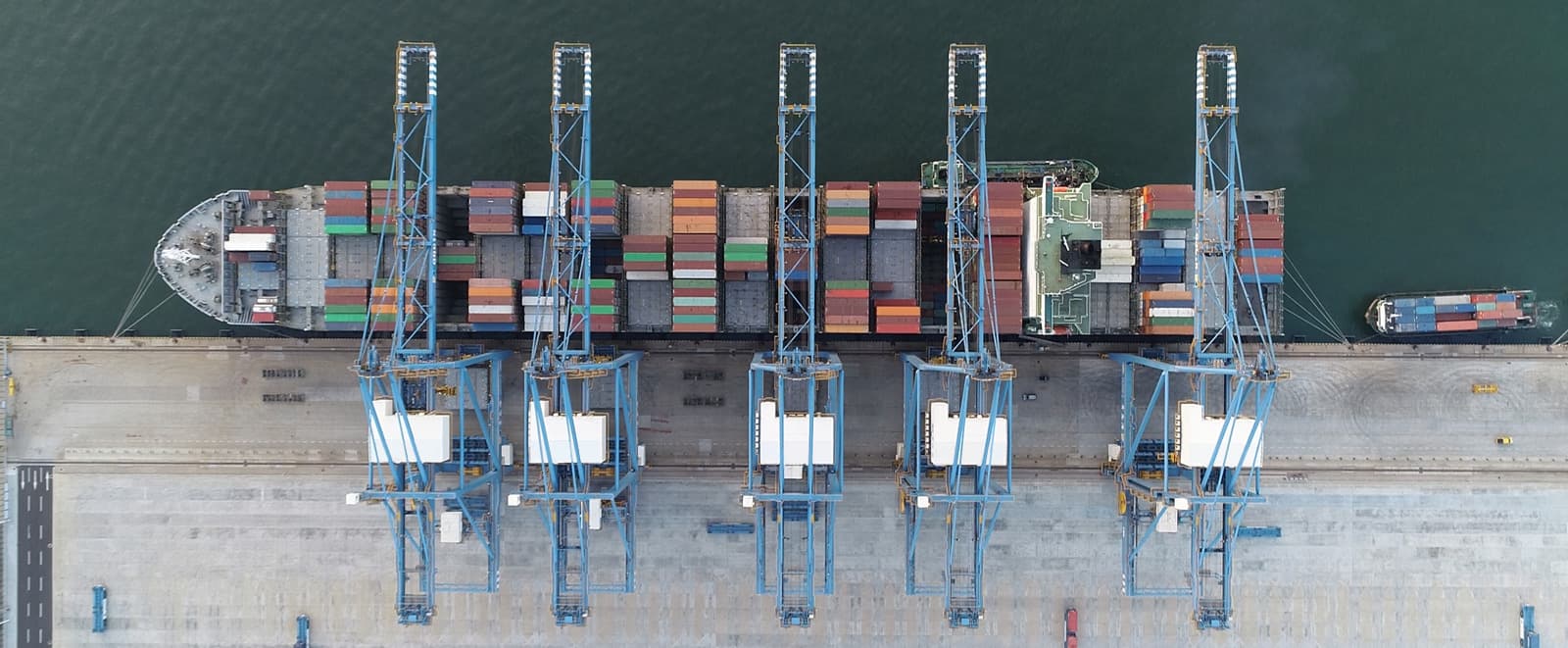

Container Handling Equipment

Each product is designed with our customers in mind

Aftersales Support

Supporting our customers from the point of commissioning. Our extensive global network of aftersales support ensures our customers get the best out of their equipment.

Latest News