RAM Spreaders was at the Breakbulk 2023 event, where they presented their first pipe spreader customer with a scale model.

Spreader Articles

read more

Big Ships: Why They Are Taking Longer In Ports

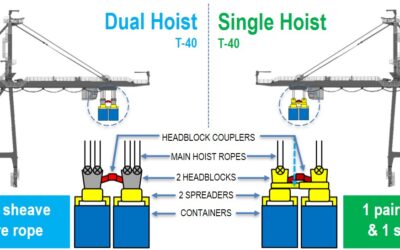

Why is tandem lifting the best choice for ship-to-shore crane container handling? This article looks at tandem container spreaders.

Ensuring Safe Operations: A look into the safety features of RAM’s mobile harbour crane spreader

In this article, we look at the safety features of RAM’s mobile harbour crane (MHC) spreaders and what ports can do to improve the safety of container handling.

Commissioned MHC Spreader

RAM Spreaders recently commissioned a single MHC spreader at a port in Georgia, by partnering with local service agents.

The Transition between Single and Tandem Container Lifting

How SingFlex headblock transitions between single and twin container spreaders, as well as considering the importance of a quick transition

Single vs dual hoist cranes in tandem lifts

This article explores why a single hoist crane with a tandem headblock attached will be a more effective investment than a dual hoist crane.

Recent Posts

RAM Spreaders win the IBJ Safety In Bulk Handling Award 2023

RAM Spreaders Refurbishes Revolvers for Port Kembla

RAM Spreaders Present Spliethoff with Pipe Spreader Model

RAM on their way to completing their Eco-friendly business initiative

TPS incorporates a new containerized copper transfer service