Our Story

RAM Spreaders has been making crane attachments since 1972.

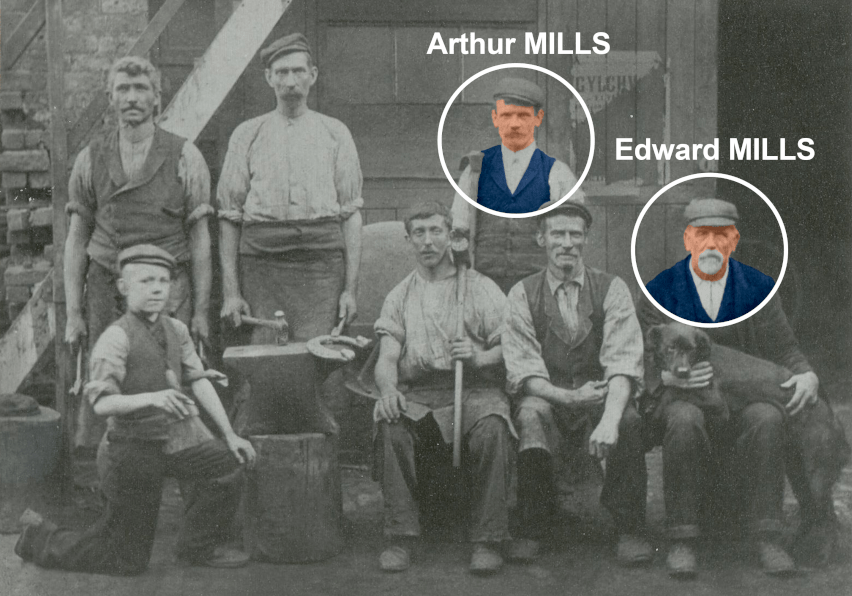

Ancestral routes

Our ancestral roots began back in 1876 as Ed Mills & Son, a blacksmith company in Liverpool, England. A thriving maritime city, which played a pivotal role in the development of the business.

RAM Spreaders

During the 1970’s and after many decades of success, the then Director of Ed Mills & Son, Robert A. Mills further diversified the company interests into container handling equipment, and soon after created the RAM Spreaders brand known today.

From the early 1990s, our company (then known as NSL Engineering) firmly established the RAM Spreaders in the container handling industry. With clever strategic market penetration & innovation, our business continued to grow with spreaders seen at ports and terminals worldwide.

Continuing to grow ever stronger

The RAM Spreaders brand continues to grow ever stronger, with products including ‘SingFlex’ multiple container lifting tandem headblock and ‘Revolver’ bulk handling spreader.

Innovations such as the telescopic Pipe Handling spreader, allow us to enter new markets, whilst continuing to support our existing customers, expand our spreader portfolio, spare parts service and after-sales support.

RAM Spreaders – now & the future

From 5 decades of experience, operating in 65 countries, covering 6 continents, and seen in terminals big and small, our success lies with our constant innovation and customer approach – “we listen to their goals, needs and then we build.”

“We believe our products can truly make a difference. With our customers’ continued faith and support, we continue to innovate and provide cost-effective handling solutions. Supporting our customers along the way with a dedicated and skilled global service and support team, essential in keeping handling operations running smoothly.”